Brake Machining Tamworth

Quality Brake Rotor Machining

Extending Your Brake’s Lifespan with our Brake Machining Service

Rather than unnecessarily replacing brake components, Kings Brake Service Specialists offer a range of machining services to recondition your brakes. We machine all brake rotors and brake drums in our Tamworth workshop. From vintage custom vehicles to race cars and trailers, our lathe fits the brakes of a diverse range of vehicles.

The friction between the brake pads and disc of your vehicle causes them to wear, increasing the time it takes for you to stop in an emergency. Maximise the life of your brake components and ensure the safety of you and your passengers by booking your car in for a service.

Experienced & Qualified Team

Our accredited team have extensive knowledge and skill in machining brakes. We’ll remove the minimum amount of material from the surface of your rotors to provide a safe area for the pads to run against.

At Kings Brake Service Specialists, we can recondition the following brake components:

- Brake shoes

- Brake boosters

- Master cylinders

- Wheel cylinders

- Clutch cylinders

And much more!

Breathe life into the drum brakes of your old farm ute or repair the discs of your passenger car with our machining services. If your vehicle’s brakes have worn past the minimum thickness rating, we can replace them with ready-made or custom-built rotors. Contact us to arrange a service.

FAQ

What is brake machining, and why is it necessary?

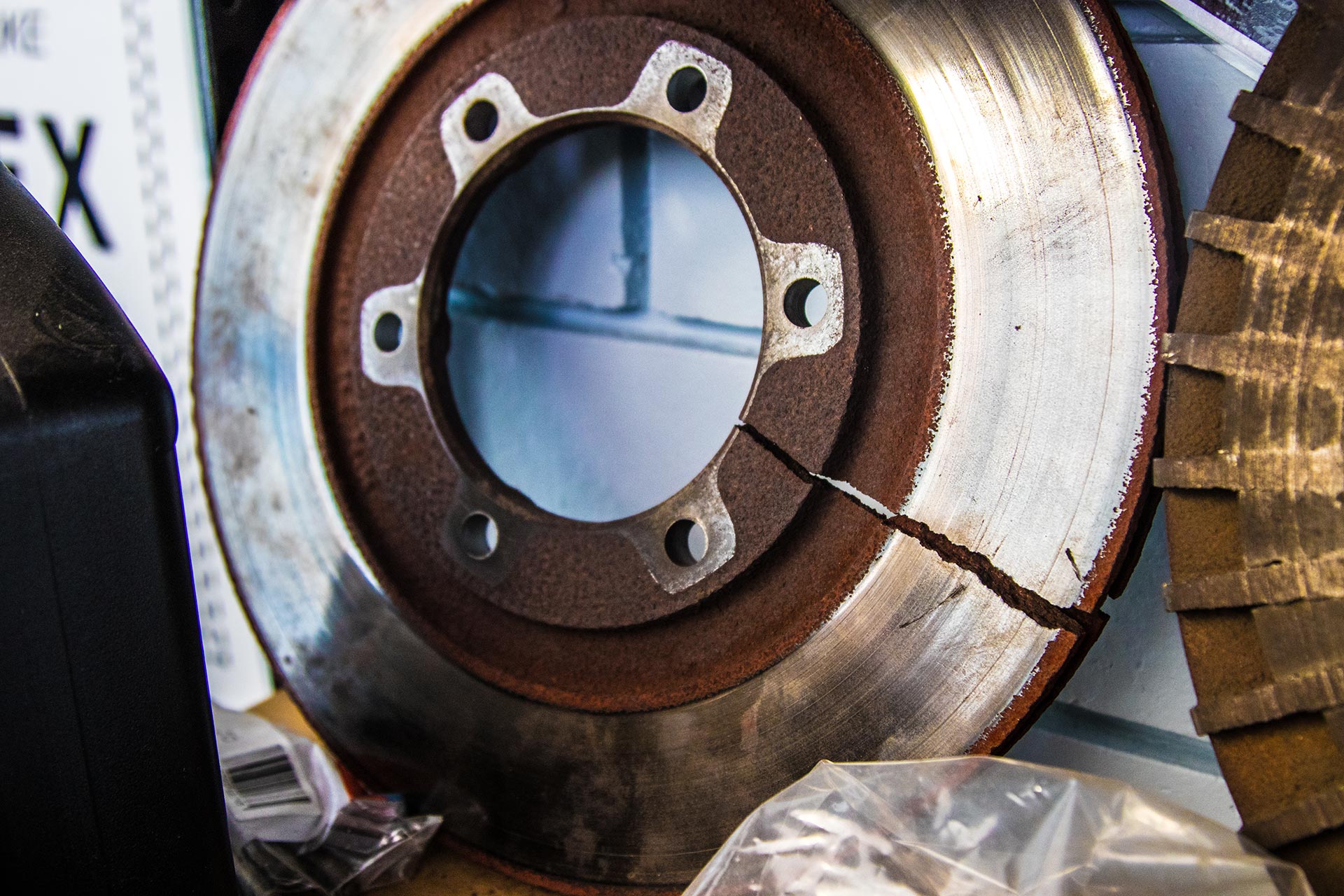

Brake machining resurfaces brake rotors or drums to remove imperfections such as grooves and uneven wear caused by friction and heat. These imperfections can impact braking performance, leading to vibrations, noise, and reduced stopping power. Machining restores a smooth, even surface, allowing proper contact between the brake pads and rotors. This helps extend the lifespan of the braking system and maintain braking efficiency, making it a cost-effective alternative to replacement when the components remain within safe thickness limits.

How do I know if my brake rotors need machining?

Signs that brake rotors may need machining include vibrations or pulsations in the brake pedal, high-pitched squealing or grinding noises, reduced braking efficiency, and visible scoring on the rotor surface. Uneven brake pad wear can also indicate that the rotors are not properly contacting the pads. If any of these issues arise, a professional inspection can help determine whether machining is a viable solution or if rotor replacement is required.

Can all brake rotors be machined, or are there limitations?

Not all brake rotors can be machined; each has a manufacturer-specified minimum thickness. If machining reduces the rotor beyond this limit, it becomes unsafe and must be replaced. Other factors, such as deep cracks, excessive warping, or uneven wear that cannot be corrected, may also require replacement. A technician will measure the rotor’s thickness and assess its condition to determine whether machining is suitable.

How often should brake machining be performed?

Brake machining is not routine maintenance but is performed as needed based on wear and braking performance. Factors such as driving habits, road conditions, and brake pad replacements influence the need for machining. Frequent hard braking, hilly terrain, and stop-and-go traffic can accelerate rotor wear. Regular brake inspections every 10,000 to 20,000 km can help assess whether machining is required to maintain braking efficiency and safety.

What types of vehicles can you service?

Many vehicles can benefit from professional brake machining services, including everyday passenger cars, high-performance race cars, vintage and classic vehicles, 4WDs, trailers, and caravans. Whether precision machining is needed for a performance vehicle or restoration work for a classic car, experienced technicians and specialised tools ensure that diverse brake system requirements are met. With the right equipment and expertise, high-quality machining services are available for various braking components.

Besides rotors, what other brake components can be reconditioned?

In addition to machining brake rotors and drums, reconditioning services are available for other essential braking components. These include brake shoes, which ensure even contact with the drum; brake boosters, which enhance braking force; and master and wheel cylinders, which are critical for fluid pressure distribution. Clutch cylinders can also be reconditioned to maintain smooth operation. If any of these components are too worn for repair, high-quality replacements can be provided to restore braking efficiency.

What happens if my brake components are too worn for machining?

If brake rotors, drums, or other components are too worn or damaged for machining, replacement is the safest option. We offer new brake rotors and drums that meet manufacturer specifications and custom-built brake parts for vintage or specialised vehicles. We also provide high-performance braking solutions for performance cars designed for enhanced durability and stopping power. Our team will assess your braking system and recommend the most suitable solution to keep your vehicle safe.

How can I schedule a brake machining service with Kings Brake Service Specialists?

Booking a brake machining service is easy. You can contact us directly or visit our workshop. Our experienced team can inspect your brakes, determine if machining is required, and provide expert service to restore your vehicle’s braking performance. For more information about our brake machining services, contact us.